Cremation is often viewed as a solemn and emotional conclusion to a life. While this is true on a human level, what happens behind the scenes is far more structured and technical than many people realise. The entire process follows a well-defined sequence, more similar to a controlled engineering operation than a symbolic farewell.

Understanding how cremation works can make things easier for families. Knowing that each step is handled carefully by professionals can help reduce any worries. The process is done with the right equipment and clear steps.

Here are twelve specific ways cremation reflects the discipline and structure found in engineering.

Before anything happens inside a crematorium, the paperwork must be complete and verified. Cremation requires official forms, approvals, and permits. These documents ensure that the cremation is lawful and that it is carried out according to the family’s exact instructions.

No part of the funeral can begin until all the necessary information is confirmed. This includes checking the person’s identity, confirming who has the right to make decisions, and completing any waiting periods. Staff review the forms carefully, check names, and confirm identities before continuing. This is similar to processes in other regulated industries.

Cremators are built to do one job, and they do it with accuracy. These machines are not general-purpose ovens. Each cremator is engineered with a system of controls, reinforced materials, and safety measures that support a precise process from start to finish.

Inside the cremator, materials are heat-resistant and durable. External controls enable the operator to manage temperatures, airflow, and timing. Safety shutoffs and backup systems are in place to prevent mistakes. These features are not merely optional; they are crucial for a system that relies on reliability and responsibility.

Once the cremation begins, heat levels rise to over 800 degrees Celsius. These temperatures are not randomly chosen. They are selected because they support complete combustion within a controlled timeframe.

Technicians monitor the temperature at all times using digital screens and sensors. Any change is noted immediately. These monitoring systems operate similarly to those used in temperature-sensitive industries, where even slight deviations can be significant. The high heat is sustained for a set period, creating uniform results that comply with environmental and professional standards.

The time it takes for a cremation can vary, depending on things like the person’s weight, the type of coffin, and the cremator used. Crematorium staff look at these factors beforehand to work out how long it will likely take.

Time estimates are not just guesses; they are based on data from past cremations, technical specifications, and material standards. As a result, the time is usually between 90 and 120 minutes, allowing staff to plan the schedule and oversee the process without disruption.

Placing the coffin into the cremator is carried out using equipment designed to support the process. Most facilities use rollers, trays, or lifts that enable the operator to guide the coffin gently and accurately into position. This minimises the risk of damage or delays.

This step is especially important in maintaining the respectful tone that families expect. At the same time, the use of equipment rather than manual handling reflects the type of controlled material movement found in industrial environments. Accuracy and safety are the focus throughout.

Modern crematoriums use computer systems that log and display live data from the cremator. These systems track internal temperature, time elapsed, and chamber status. This allows operators to monitor multiple factors at once, even from a distance.

The software does not replace staff supervision but supports it. It allows data to be checked later to make sure all procedures were followed correctly. It also helps spot technical problems early, so work can continue smoothly. This kind of control is similar to what is used in places where accuracy and consistency are important.

After the cremation finishes, the chamber is left to cool. This step is not rushed. Opening the cremator too soon can result in safety hazards or material damage. The cooling phase is built into the cremation timeline and monitored by the same systems that controlled the heating stage.

Once the temperature falls to a safe level, remains are removed using tools and placed on a heat-safe surface. Skipping or shortening this step would increase the risk of injury or incomplete results. The fact that it is treated as essential shows how closely cremation follows disciplined process management.

After cooling, the remaining bone fragments are placed into a device called a cremulator. This machine grinds the fragments into the fine ash that families receive. The cremulator is not a random accessory—it is a specialised machine with settings and controls that define the consistency and timing of the result.

Each use of the cremulator is timed. Staff load one person’s remains at a time and supervise the full cycle. The goal is to create a uniform, respectful result without contamination or mixing. This stage adds another layer of mechanical accuracy to the process, leaving no room for uncertainty.

From start to finish, each person is given a heat-resistant metal tag. This tag has a number that matches the records kept by the crematorium. It stays with the coffin during the entire process and can be seen at every stage.

Staff carefully inspect the tag at every step. After the cremation, the ashes are matched to the tag to make sure they belong to the right person. This means each family gets only their loved one’s ashes. The system uses reliable tracking, like in other strict industries.

After each cremation, the chamber is thoroughly cleaned and reset. This ensures that ashes from one person do not get mixed with those of another. Staff use special brushes and vacuums built to withstand high temperatures to remove any leftover particles.

The machine is then set back to its normal settings, ready for the next cremation. This is not a quick task. It is a regular and important part of the process, just like the cremation itself. It is similar to how clean rooms or laboratories work, where stopping contamination is very important.

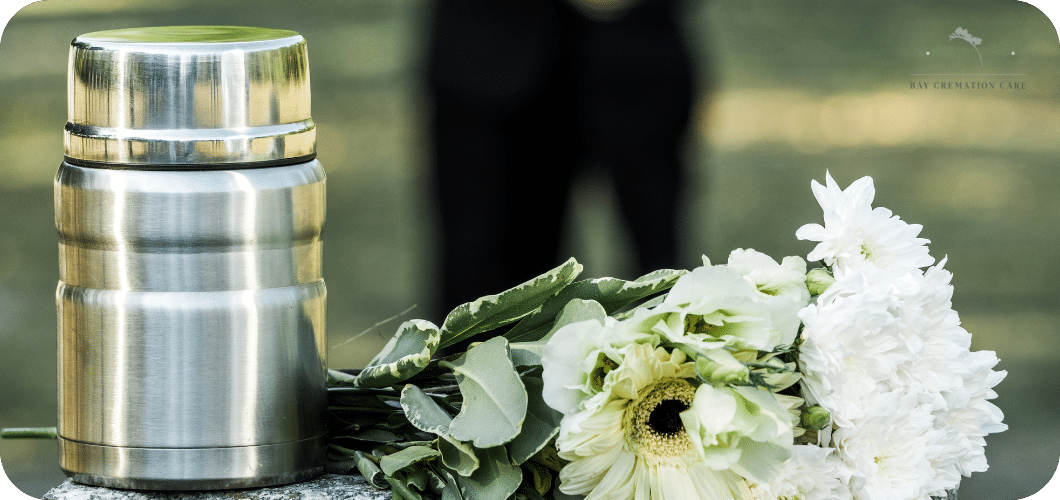

When ashes are collected, they are placed into a container chosen by the family. The container is sealed and labelled using the person’s full details. These labels are printed from the crematorium’s system and cross-checked before the ashes are moved.

Staff follow a step-by-step checklist to confirm that each part of the packaging is correct. This includes labelling, sealing, and record entry. The process may seem simple on the surface, but the same attention to detail governs it, from order and tracking that runs throughout the entire cremation.

Before ashes are given to a family or transferred elsewhere, staff complete a formal handover. This includes checking records, confirming the recipient’s identification, and updating the system to reflect the completed return.

This final step may feel ceremonial, but clear procedures drive it. Every handover is recorded. No detail is left open to guesswork. Families receive their loved one’s ashes knowing that every step from intake to return followed a plan, checked and rechecked along the way.

Cremation may feel emotional from the outside, but behind the scenes, it is a carefully planned, controlled, and consistent procedure. Every step follows a clear system that combines compassion with technical precision.

At Bay Cremation Care, the focus is on respect and reliability. Each cremation is conducted safely and professionally, with meticulous attention to ensuring the correct identity is verified. The process may seem more like a technical job than a farewell, but that is why it can be trusted. Families can feel assured that everything is done carefully and exactly right.

At Bay Cremation Care, we are dedicated to providing everyone with options for planning an affordable yet meaningful funeral service at our funeral home in Tauranga.

We are passionate about doing everything we can to give your loved one a beautiful, respectful, memorable farewell and alleviating your pain in this challenging time.

We believe that a funeral plays a vital role in offering closure and catharsis after a loss. That is why we will go out of our way to provide you with caring, attentive service.

Based in the Bay of Plenty, Bay Cremation Care has been offering the people of Tauranga and its surrounding areas compassionate care and support in their most challenging times. The company is run by Alistair Black, a fully qualified Funeral Director, Embalmer and member of the Funeral Directors Association of New Zealand (FDANZ) and NZ Embalmers Association.